Environmental Strategy

TPL understands the importance of managing our environmental footprint and as such, we prioritize critical environmental issues such as energy efficiency, emissions management, and ecological due diligence to minimize environmental risks to our operations. Given the differences in our operating segments, we implement different strategies to effectively manage these issues across our Land and Resource Management segment and Water Services and Operations business.

To measure our progress across all assets, we track a variety of key performance metrics, including those associated with our emissions footprint and ecological and biodiversity indicators. By measuring our performance, we are able to identify areas in which we excel and areas that may require additional resources, allowing our Company to continue progressing forward. As we shape our forward-looking strategies and decision-making, our Board of Directors (the “Board”) and management team prioritize these sustainability areas of focus and continue to identify ways in which we can improve our operational footprint.

We Set High Expectations for Our Partners

Texas Pacific is unique when it comes to environmental sustainability, particularly as it applies to surface interactions with oil and gas exploration and production (“E&P”) companies. Except for the Company’s Water Services and Operations business, we do not directly develop or operate the infrastructure on our lands and our legacy assets do not include mineral rights. As a result, TPL has limited influence over E&P operations on our lands. Nevertheless, we maintain close relationships with our lessees and operators to support and encourage sustainable operating practices that align with our ESG goals and targets.

Our extensive surface assets allow us to partner with E&P companies. These companies collaborate with TPL throughout the cycle of their operations, from initial infrastructure development to drilling and completions and finally, production. We enable and foster lasting partnerships throughout the lifecycle of resource development.

TPL relies on and expects operators to conduct their business in accordance with sustainability best practices and accountability. Where applicable, all of our existing and new operators abide by contracts and guidelines established by TPL, and we have included certain ESG requirements in these documents to reflect our sustainability commitments.

Additionally, given our strategic partnerships with the E&P industry, we continue to seek and develop new opportunities to work together and augment our collective ESG commitments and projects. The energy industry is a leader in ESG disclosure and reporting, and it is prudent for companies to partner together to align our ESG goals and drive beneficial sustainability synergies.

Task Force on Climate-Related Financial Disclosures (TCFD)

Our approach to managing climate risks and opportunities aligns with the recommendations of the TCFD. Through the identification of climate-related risks and opportunities, we are able to implement the appropriate risk mitigation and opportunity capitalization strategies, thus contributing to the long-term success of our business.

Governance

Board Oversight of Climate Risks

Our Board is responsible for overseeing the Company’s operations including its strategy, risk management, and performance of management, to align with the interests of our stockholders. The Board also works to ensure our strategic business operations are conducted in accordance with our ESG program standards, which include climate change risk management.

The Board has four standing committees that meet quarterly and on an as-needed basis to help oversee the Company’s business: the Audit Committee, the Compensation Committee, the Strategic Acquisitions Committee, and the Nominating and Corporate Governance Committee (the “N&G Committee”). Each Board committee member brings distinguished skills and capabilities enabling oversight of sustainability and ESG goals. However, oversight of climate risks and opportunities rests with our N&G Committee.

The N&G Committee ensures ESG programs are conducted with the highest levels of integrity and responsibility. The N&G Committee’s charter stipulates that it will “review the Company’s policies and programs concerning corporate social responsibility, including environmental, social and governance (ESG) matters” and “provide guidance to the Board and management with respect to trends and developments regarding environmental, social, environmental and political matters that could significantly impact the Company."

Management’s Role in Assessing and Managing Climate Risks and Opportunities

TPL’s ESG Leadership Committee provides critical oversight and direction regarding our ESG and climate-related business strategies. Our CEO, CFO and Senior Vice President & General Counsel are members of this Committee.

Our ESG Working Committee reports to the CEO and is led by our Vice President of Corporate Strategy. It is comprised of our management level, cross-functional subject-matter experts, and offers division-specific knowledge and accountability related to the ongoing development and evaluation of our ESG initiatives. One of the most frequent topics of discussion for this committee is our focus on our renewable energy development strategy. ESG strategic risks are included in our overarching Enterprise Risk Management (“ERM”) program. TPL assigns an executive to manage and monitor the effectiveness of the processes and controls surrounding each strategic risk within the ERM program.

Strategy

Climate-Related Risk Identification and Mitigation

Our strategic approach to managing climate events represents a critical component of our broader, long-term business strategy at TPL. We are factoring in the risks and impacts of climate events to our economic, environmental, social, and governance decisions to ensure we remain committed to responsible operations.

As part of our ERM framework, TPL has identified the following examples of climate-related risks that could potentially impact our business:

| Climate-Related Risk | Risk Description | Risk Mitigation Strategy |

|---|---|---|

| Legal and Regulatory Risks | The potential inability to anticipate and/or properly respond to changes in the regulatory environment could negatively impact TPL’s ability to create value for our stockholders. Changes to legislation or regulation related to a tax on production volumes, greenhouse gas (“GHG”) emissions, or other environmental elements could lead to increased operating costs and/or reduction in profits. | TPL’s full Executive Leadership Team and Board regularly monitor and discuss the evolving political and regulatory environment around potential emerging risks from pending or changing legislation or regulations. |

| Reputational Risks | Potential inability to effectively manage environmental footprint and respond to increasing requests from internal and external stakeholders for sustainability information may lead to reputational damage. Regardless of the source of reputational risks, any potential reputational damage to TPL has the possibility to impact our business in many ways and impact our relationship with numerous stakeholders. Reputational risks could negatively impact our brand and thus our relationship with customers, which could impact revenue generation. Beyond this, it can hurt our relationship with our employees and communities, which may impact our ability to sustain normal operations and grow as a company. Changing investor and prospective lender sentiment about our reputation further has the potential to impact our access to capital or ability to attract new investors. | TPL navigates potential reputational risks by striving for continuous improvement within our operations, while also regularly engaging with various stakeholders to understand and internalize their perspectives and opinions. This drive for continuous environmental performance improvement is part of our effort to protect our reputation as a responsible operator. Meanwhile, our commitment to stakeholder engagement enables us to monitor evolving expectations from employees, suppliers, customers, investors, landowners, and our communities. For example, some of our landowner relationships have existed for more than 100 years, and their expectations from TPL have changed over time. We regularly engage with them, and other stakeholder groups, as part of our process to manage reputational risks. Additionally, TPL maintains and updates in-depth disclosures on our ESG program, providing stakeholders throughout the value chain with transparency into our responsible business practices. |

| Technology and Market Risks | Technological developments will be a key component in energy efficiency. TPL recognizes that the evolution of global energy sources is partially affected by factors out of our control, such as the pace of technological developments and related cost considerations, the levels of economic growth in different markets around the world, and the adoption of climate-related policies. The pace at which technology develops could impact TPL’s ability to operate more sustainably. Further, varying economic growth situations and climate policy evolutions could impact both the profitability and viability of our business in the long term, as much of the value of the land we own and upon which we receive royalties is based on the oil and natural gas reserves located there. TPL regularly monitors evolutions across these areas. | TPL has a culture of continuous improvement across all of our teams, and this culture shows itself in our approach to innovative technology. One key component of this is that we regularly assess evolving technologies that have the capability to change an industry or help improve the environmental efficiency of our operations. We have implemented advanced technologies in our operations, such as the electrification of assets and produced water treatment and reuse, and we proactively work to remain informed of new technological opportunities. |

| Acute Physical | Acute physical risks include possible abnormal changes in weather events and natural disasters, both of which could disrupt TPL’s business. Extreme weather events could possibly impact delivery of our services, which could lead to lost revenue, missed opportunities, and strained client relationships. | TPL also works diligently to monitor and mitigate physical risks. For acute risks, TPL works with our lessees to encourage and focus on the resilience of our operations and their operations, being able to withstand extreme weather conditions to the extent possible. |

| Chronic Physical | Chronic physical risks include possible abnormal negative changes in precipitation patterns and abnormal variability in weather patterns, along with a gradual shifting in broader climate patterns. Chronic physical risks could include prolonged drought and aquifer decline within our lands, resulting in lost revenue and/or missed opportunities, which could disrupt our operations and impact the performance of the operators that rely on water resources to source oil and gas within our assets. | For chronic climate risks, TPL analyzes these trends both in the context of the location of our assets and the environmental responsibility of our lessees. |

Risk Management

Our ERM framework includes an assessment of vulnerability to enterprise risks and lays out a Risk Mitigation Plan for each risk, including the examples of climate change-related risks identified in the Strategy section. The executive management team member or delegate assigned to each risk mitigation plan is responsible for advancing key solutions, including those for climate-related risks. By incorporating climate-related risks to our ERM strategy, we are able to proactively track and monitor the various risks that can result in material, destructive impact to our operations, financials, and reputation.

We have processes and protocols in place to monitor the potential impacts of climate-related risks on our own operations, which are part of our broader risk management program. While the nature of climate-related risks, and risks in general, is complex, we use the following matrix of frequency and probability as a starting point to assess critical risks to our business.

| Rating | Annual Frequency Descriptor | Frequency Definition | Probability | Probability Definition |

|---|---|---|---|---|

| 5 | Very Likely | Up to once in 2 years or more | Almost Certain | 90% or greater chance of certain occurrence over life of asset, project or company |

| 4 | Likely | Once in 2 years up to once in 10 years | Likely | 65% up to 90% chance of occurrence over life of asset, project or company |

| 3 | Possible | Once in 10 years up to once in 25 years | Possible | 35% up to 65% chance of occurrence over life of asset, project or company |

| 2 | Unlikely | Once in 25 years up to once in 50 years | Unlikely | 10% up to 35% chance of occurrence over life of asset, project or company |

| 1 | Rare | Once in 50 years or less | Rare | <10% chance of occurrence over life of asset, project or company |

These identified risks are accompanied by critical information about root causes and potential impacts in order to facilitate discussions of applicable, actionable, and measurable mitigation plans. Throughout the year, TPL assesses and defines the potential material risks to our business and allocates risk ownership accordingly to an executive member or team that then updates the ERM document accordingly. Our ERM program is managed by the executive management team and overseen by the Audit Committee of the Board.

The following criteria is used in assessing risks identified by management, including climate-related risks:

Impact

Impact (or consequence) refers to the extent to which a risk event might affect the enterprise.

Likelihood

Likelihood represents the possibility that a given risk event will occur, expressed using qualitative terms such as frequency or percentage probability.

Velocity (Speed of Onset)

Velocity or Speed of Onset refers to the time it takes for a risk event to manifest itself, or in other words, the time that elapses between the occurrence of an event and the point at which the Company first feels its effects.

Vulnerability

Vulnerability refers to the susceptibility of the entity to a risk event in terms of criteria related to the entity’s preparedness, agility, and adaptability.

Beyond identified risks, our ERM Assessment also works to identify and mitigate emerging risks, as TPL is aware that risks can either gradually emerge over time or present themselves overnight. The ERM is embedded into every aspect of our business decision-making to deliver enhanced and predictive returns for our stockholders. This process includes assessing legal and compliance obligations, the energy transition, potential natural disasters, extreme weather events, and more.

Metrics and Targets

Metrics

Quantitative data enables us to track and meaningfully manage climate risks and opportunities. Our metrics and KPIs provide a foundation to guide the Company’s current and future strategic business decision-making. We view the tracking and disclosing of environmental performance data as the first key step towards systematically approaching climate risk management. 2024 data is tracked and disclosed below. TPL remains dedicated to the continued aggregation and analysis of this data to monitor and trend our progress against our baseline.

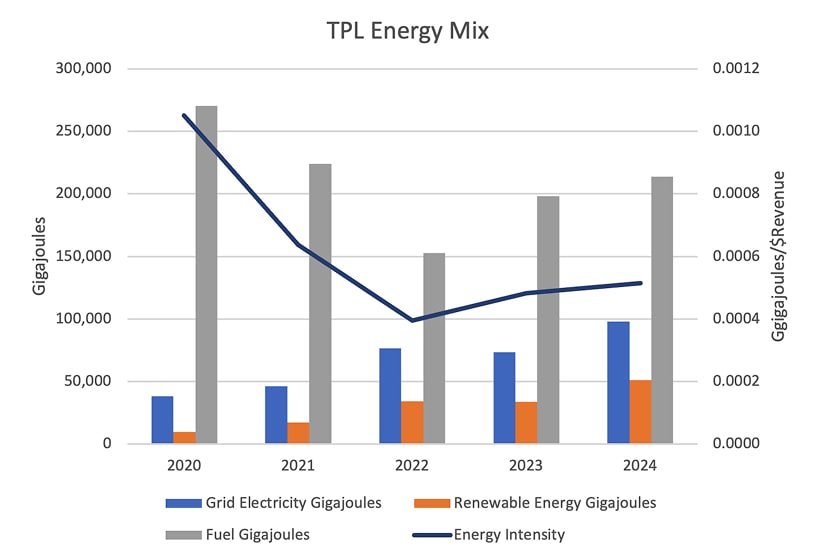

At TPL, we use Scope 1, Scope 2, total energy consumed (gigajoules), percentage of energy type, and electrification to assess climate-related risks and opportunities in line with our strategy and risk management process.

As demonstrated in the graphs below, over the last 4 years, TPL has continued to reduce its emissions intensity while increasing the use of grid electricity and renewable energy within our energy mix. We will continue to track our performance in this area and monitor the effectiveness of our efforts to mitigate our carbon footprint.

Emissions and Energy Management

Reducing our footprint is a focus of our environmental stewardship commitments, and we have made significant progress over the past few years through new strategic partnerships, asset retrofits, and operational advancements that have enabled significant reductions in our emissions intensity.

When looking at our two business segments, Land and Resource Management and Water Services and Operations, our only owned operations are within the water segment. Therefore, our ability to manage our carbon footprint within the Land and Resource Management segment is focused on our work with lessees that operate on our land. In addition to working with lessees throughout our operations, we track and monitor emissions across all our water operations. These activities enable our team to understand our emissions footprint, resulting in our ability to implement targeted initiatives and technologies that allow TPL to efficiently reduce emissions.

Electrifying Our Operations

TPL’s largest opportunity to mitigate and reduce our emissions is through Texas Pacific Water Resources, as TPWR represents the only operations TPL owns and manages. To mitigate emissions of TPWR, we implemented a series of electrification projects across our water assets which reduce our reliance on diesel.

Leveraging the results of a thorough analysis of our water assets, TPL prioritized the high-utilization, high-impact assets for electrification to remove the reliance on diesel, resulting in a greater reduction in emissions. We continue to allocate capital and assess the future of our electrification projects to continue our progress in this area. To date, we have spent $22.3M on electrification, and the impact of these retrofits is visible.

Although electrification is the goal as a primary power source, TPL has diesel generators as backups for all assets to ensure operations continue to run in an emergency power-outage scenario. Events such as the 2021 Texas freeze, which highlighted infrastructure vulnerabilities across the Permian Basin for both water management and oil and gas companies, underscore the importance of having these backup energy sources.

In support of our lessees, we can help reduce their emissions footprint through the construction of easements on our land to build electricity infrastructure, supporting oil and gas operators’ access to electricity and thus avoiding the use of diesel to power their operations. Although we cannot directly control or measure their emissions footprint, this innovative solution is one of the ways we can act as a good partner to these companies.

Energy Efficiency

TPL has processes in place to track energy consumption by location, both electric and diesel, covering 100% of the energy used. As part of our commitment to reducing energy consumption, TPL has implemented a variety of energy efficiency measures. These energy efficiency measures include items such as:

- The purchase of electrical pumps to move water, which decreases our diesel usage;

- Implementing auto-shutoff lights in an effort to conserve energy and improve our energy efficiency.

We will continue to explore ways in which we can improve our energy efficiency by incorporating new, innovative technologies throughout our operations.

Renewables and “Next-Gen” Development

Not only are we focused on our own emissions profile, but we are also enabling oil and gas operators to reduce their emissions. We feel that our land holdings uniquely position us to promote and inspire innovation across the clean energy market and support the energy transition.

In 2022, we expanded our Renewables (“Next-Gen”) Team, a team created to solely focus on encouraging wind and solar development on our properties and exploring all available options to increase our existing renewable footprint. The team strategically prioritizes increasing our existing renewable portfolio through industry outreach and dedication to navigating complex regulatory considerations across infrastructure development.

Currently, we host around 120MW of wind power and our land holdings play a critical part in supporting infrastructure related to an additional 100MW of solar power. We partner with developers who can create over 100 MW of commercial-grade projects by executing long-term purchase power agreements (PPA). We are also working with our current partners across the Permian Basin to implement micro-grid sized projects (typically 5-50MW) that will allow traditional oil and gas companies to reduce their own carbon footprint by supplementing grid power with cost-efficient and reliable green energy.

Our unique operating model allows us to pursue opportunities to increase our renewable portfolio. Energy produced by our renewable operations can be sold back to the grid or used to offset our own electricity consumption. TPL has over 500MWs of contracted agreements on our land for renewable operations, including solar and wind.

Carbon Capture and Sequestration

TPL’s expansive surface footprint can serve as a key resource to permanently sequester carbon. We are constantly looking for ways to leverage the unique features of our assets, and carbon capture is an exciting opportunity that could serve a dual purpose of creating value for our stockholders while also benefitting the environment.

As a landowner and water operator, our emissions footprint is minimal. Yet, we know we have a critical solution for the oil and gas entities that operate on our land to mitigate and reduce their own emissions. Carbon sequestration provides opportunities for oil and gas companies to meet, or even outpace, their emission reduction targets. Incentives around sustainable energy projects, such as carbon capture, utilization, and storage (“CCUS”) enable our Company to act as a steward of the environment. As operators and consumers look to reduce the carbon intensity of fossil fuel products, carbon capture and sequestration projects will be necessary to produce and acquire these cleaner products.

Our land acts as a carbon sequestration solution to permanently store the carbon that directly results from oil and gas operations. Due to the geological characteristics of our land, we can offer operators environmentally permitted pore space that is needed within or near the Permian Basin. Permanent sequestration is not possible without land that can offer this emissions management solution—that is exactly what we provide. In 2023, two major projects were signed, both of which have been progressing throughout the past year to drive CCUS.

Ozona and Milestone Carbon CCUS Projects

In 2023, TPL signed agreements with Ozona CCS LLC and Milestone Carbon, LLC to explore and implement long-term infrastructure solutions to capture, transport, and sequester carbon to support operators both on our land and in the region more broadly. As part of these agreements, the partners will lease approximately 25,000 acres of land within the Permian Basin for carbon sequestration. Over the past year, we have been working to advance these agreements and continue with the development of CCUS projects that lessen the carbon impact of operators in the Permian Basin.

Biodiversity

As a landowner, protecting biodiversity in the areas where we operate is part of our commitment to corporate responsibility.

Environmental Impact Assessments

Texas Pacific’s Environmental Management System (“EMS”), aligns with ISO14001 as a recognized environmental management standard. This guides our environmental impact assessment processes in Texas & New Mexico. Our EMS is overseen by the Health, Safety and Environment (“HSE”) Department who reports to SVP and General Counsel.

It is standard practice to conduct on-site Phase 1 Environmental Site Assessments to gauge the condition of property prior to the Company acquiring additional surface acreage. As part of its operational excellence due diligence, TPL also tests for chlorides.

To manage the integrity of existing pipeline assets, we schedule regular pipeline maintenance checkups, and the HSE team closely monitors assets for spills, leaks, or any other type of release.

Ecological and Biodiversity Partnerships

TPL fosters partnerships with environmental experts, such as the New Mexico Bureau of Land Management, to obtain biodiversity impact guidance and vital insight into environmentally sensitive areas. Through these partnerships, TPL proactively manages and avoids environmentally sensitive areas or, when appropriate, proceeds with caution and applies environmental due diligence.

We contractually require our grazing tenants to use proper grazing and stockman standards as well as participate in conservation, range, and wildlife improvement programs when possible.

TPWR also works closely with oil and gas operators to follow their established biodiversity protocols.

Prior to the buildout of any new water midstream assets, we partner with our environmental consultants to obtain environmental and ecological information that could impact the development and/or expansion of water operations. These consultants utilize ArcGIS software to capture and report data that shows if TPL’s planned infrastructure intersects with environmentally sensitive areas. The current process allows the Company to proactively manage and mitigate construction on land with conservation status, high biodiversity value, endangered species habitat, and Unusually Sensitive Areas (as defined by SASB). Additionally, the Company employs land surveyors who act as on-the-ground resources to confirm the environmental intelligence obtained from the software.

Leveraging insights gained from our site assessments and partnerships, we seek to ensure any operators who approach TPL about constructing new infrastructure on our land will avoid impacts to biodiversity or cultural resources. We believe these practices mitigate any unknown environmental risks or potential information gaps not captured by virtual assessment tools.

It is also important to note that TPL encourages, and where applicable requires oil and gas and midstream operators to build their assets in specific, designated land corridors to avoid unnecessarily disturbing land and to minimize environmental footprints. TPL’s pipeline leases have stringent contractual obligations to ensure environmental due diligence and responsible land management.

Operator and Lessee Requirements

TPL prioritizes consistent engagement and communication with operators and lessees on TPL’s land to ensure environmental due diligence is maintained. The requirements outlined in TPL’s contract language with operators and lessees cover expectations for responsible operations during and after use of all TPL land. Lessees are expected to preserve and protect the natural environmental conditions of the land, which includes preventing, and if necessary, remediating, any instances of contamination, spills, or other types of environmental damage.

Under our agreements, all lessees are required to follow all applicable environmental laws pertaining to the protection of human, health and safety, natural resources, the environment, regulation of oil, gas and other mineral exploration, production and transmission, and the regulation of remediation of chemicals, contaminants, or hazardous materials, including those outlined in the Resource Conservation and Recovery Act of 1976, Comprehensive Environmental Response, Compensation and Liability Act of 1980 (CERCLA), as well as Texas Health & Safety, Water, and Natural Resources Code.

We have field personnel who regularly visit and monitor our asset areas. If an issue were to arise, the field personnel would notify an employee on the surface team to reach out to the responsible operator. In the event that a lessee violates the terms of a contract resulting in a change to the environmental conditions of the land, TPL may require the lessee to promptly engage in the appropriate remediation procedures.

Land Reclamation

When an operator or lessee comes to the end of a lease or is leaving TPL’s land, TPL requires a reclamation process to verify that the land has been restored to the environmental condition stipulated by the contractual agreement. Lessees are required to take reclamation or corrective actions that are accepted soil and water conservation practices to protect the land from pollution, erosion, noxious weeds and plants, or other environmental degradation.

As part of these corrective processes, lessees may be required to remove all facilities, structures, and equipment present on the land and reclaim the land by grading, leveling, terracing, or contouring any areas disturbed by construction, maintenance, and use of the site. Landscaping must also be performed to return disturbed areas to their natural state to prevent water and wind erosion, including reseeding and revegetating such areas with native grasses.

In cases where TPL finds misalignment with the level of expected remediation, TPL works with the operator and/or lessee to complete all remediation efforts necessary.

Waste & Chemical Management

TPL’s chemical management program abides by the stringent specifications provided by operators. TPL holds itself and its operators and lessees accountable to these procedures and stringent expectations.

Incidents and Spill Prevention Control

At Texas Pacific, we understand that spill prevention and control are key to responsible land and water management. Protecting the environment and our surrounding communities is fundamental to our operations and long-term business strategy.

To ensure the continued integrity of our operations, we have implemented a Spill Prevention, Control, and Countermeasure (“SPCC”) plan and protocol for our water assets. These assets are also equipped with advanced technology and secondary containment protections to prevent spills or leak risks. Our advanced operating equipment allows the operations team to automatically shut down equipped assets if an emergency scenario arises.

TPL strives for excellence; thus, we track and monitor all spills, regardless of size even if they are small enough to be outside regulatory reporting requirements. All spill information is entered into our centralized database where it can be easily tracked and managed, facilitating proactive preventative measures.

TPL has an excellent record of preventing spills. This is attributed to employee training and exceptional asset management and integrity protocols. That said, it is best to be prepared: TPL prioritizes the continued education and engagement of employees and contractors to ensure they are equipped to manage emergency scenarios. For example, the entire operations team participates in TPL’s Spill Champion Program, which provides on-site training to our employees that are most likely to encounter issues or emergencies that come from transporting liquids, including brackish water and liquids with hydrocarbons.

If a spill does occur, TPL operators and field HSE coordinators have a defined process and protocol to survey the spill and confirm its extent. There is a process to notify the proper channels within TPL to ensure oversight, and a certified third-party partner is retained if remediation services are required. Additionally, a local accredited laboratory provides soil sample assessments before and after remediation.

Water Management, Sourcing, and Supply Resiliency

TPL is committed to responsible water management strategies throughout each segment of its business. It is important to note that TPL does not have field operations; rather, we manage the surface acres that house third-party operators, such as E&P oil and gas companies. While these companies use water in their oil and gas operations on our land, this water is not attributed to TPL. We have no direct water usage associated with revenue generation across any of our operations.

The Executive Vice President of TPWR is responsible for high-level oversight of TPL’s water management strategy and provides regular updates to the CEO. This role is supported by a team of regional water managers who manage day-to-day activities, such as checking well levels and monitoring production data. Each member of the TPWR team communicates regularly to ensure TPL’s water strategy is monitored and maintained.

We formed TPWR in 2017 to support E&P companies’ operations by meeting demand for sourced and recycled water resources. We facilitate the development of infrastructure to provide water midstream services that enable the gathering, reuse, and recycling of produced water, all of which help operators minimize freshwater demand. As part of TPL’s Water Services and Operations segment, we also offer water analytics and well testing to ensure water is managed responsibly.

Our water recycling capabilities allow operators to minimize the use of freshwater resources, which is becoming an increasingly critical business strategy in Texas and is essential to manage the risk of water availability. The Company has also prioritized the electrification of our water assets to reduce reliance on diesel and to manage our emissions profile.

Notably, TPWR does not operate saltwater disposal wells (“SWDs”), but requires SWDs drilled on our property by third parties to meet industry and regulatory standards.

Integrating Water into Risk Assessments

TPL’s operations include protections and processes that help address the risks of climate change. In alignment with the TCFD recommendations, TPL has identified water availability as a key business risk. TPL is actively addressing this concern by utilizing advanced technology where possible and building operational processes that support responsible resource usage.

In addition, TPL incorporates water into its quarterly enterprise risk management analysis covering all operations in which the Company identifies relevant enterprise risks, mitigation strategies, and performance indicators. Based on findings from the risk analysis, TPL monitors well development activities, produced and sourced water capture rates, and sourced water costs, allowing our team to optimize the use, reuse, and management of water resources.

Groundwater Monitoring & Precipitation Tracking

TPL conducts groundwater monitoring in order to evaluate level changes in producing aquifers. Combined with production data, this allows us to adapt production based on the level and overall health of the aquifer.

Since 2018, TPWR has developed multiple water well-fields on TPL’s surface land position across both the Midland and Delaware Basins. As water demand and subsequent production rates increase, decreased aquifer recharge can create operational risks associated with aquifer decline. To address these risks, TPWR continued its efforts to install level monitoring equipment in water wells across well fields in Reeves County and Loving County, Texas. This monitoring equipment is placed in TPWR’s most active well fields. For wells without devices, the Company monitors static and dynamic well levels, actively reducing energy use to align with the availability of water. TPL also has implemented data sharing with the Reeves Groundwater Conservation District.

Utilizing data gathered from monitoring wells combined with pumping data collected across production wells, TPL actively monitors and manages groundwater levels throughout water sales operational areas. To supplement these monitoring activities, we also track the drawdown of water tables. If a water table is getting low, TPL can make an informed decision to move locations until that area is recharged. We also explore options such as adjustments of pump and well depth, drilling of additional wells to supplement volumes, sourcing contract amendments to supply treated or raw produced water, and/or investments in additional treatment infrastructure.

Utilizing Automation for Water Production and Treatment

Our automated volume-tracking infrastructure exists on all active water production and treatment assets.

- Brackish Water: automated meters collect all water produced, stored, transferred, and eventually sold to customers.

- Recycled Water: the same automated processes are installed on localized treatment systems.

Water wells are automated through Variable Frequency Drive pumps—this enables control of the asset and provides the ability to shut off production when needed, allowing TPL to control water withdrawals and water movement. These motors slow correspondingly to minimize consumption and proactively prevent negative environmental impacts on the aquifer. Assets also have a Global Systems for mobile backup as a redundant option should there be a critical service outage.

Sourcing and Reusing Water

Our monitoring and response capability is vital to supporting sustainable operations and managing the risks and impacts of climate change.

TPL understands the criticality of responsibly managing water as a natural resource. The Company focuses on the development of brackish, non-potable water, with the majority of our water production occurring from these brackish aquifers. Freshwater development is limited only to cases where brackish water is not geologically feasible.

As part of its commitment to responsible water management, TPWR operates a specialized lab dedicated to advanced beneficial reuse of produced water. This facility, located in Midland County, contains a variety of native plants and soil from Midland, Loving, and Reeves counties. The plants receive treated produced water and are then analyzed by researchers to assess plant health and soil conditions. The test facility has shown that treated produced water can be reintroduced into the water cycle, which reduces the need to introduce new water. Using these results as guidance, TPL educates regulators, legislators, and the public about produced water and the work being done to convert it to beneficial reuse. We look forward to continuing to scale this technology to a larger field that is being built in Reeves County.